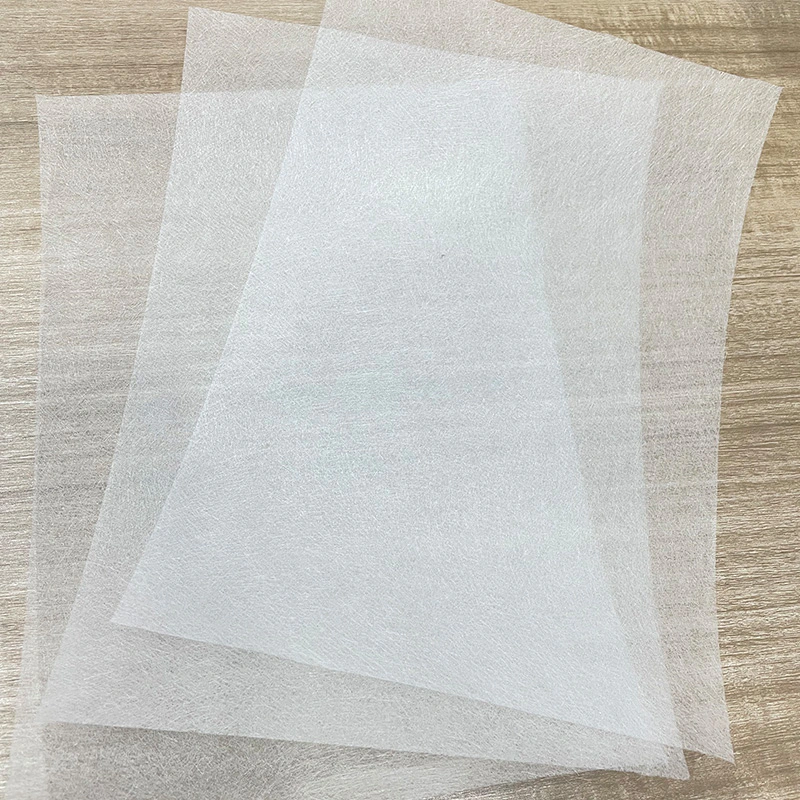

Behind many industrial products we encounter daily lies a seemingly inconspicuous yet crucially important material: the Fiberglass Tissue Mat, sometimes also referred to as a "fiberglass surface mat" or "fiberglass surface veil." It is not a standalone structural material but rather an auxiliary reinforcing material used for the surface and inner layers of composite materials. With its thin form, uniform fiber distribution, and unique physical and chemical properties, it plays a core role in numerous fields. It can significantly improve the surface quality of composite products, enhance their durability, and impart special functions, thereby bringing about a revolutionary improvement to products from the inside out.

The Manufacturing Process of Fiberglass Tissue Mat: The Art of Wet Lay-Up

The production of a Fiberglass Tissue Mat is a precise industrial process, with the most common technology being wet lay-up. This process can be figuratively understood as a type of "paper-making" technique. First, specially treated chopped glass fiber strands are uniformly dispersed in water to form a fiber slurry. This step requires precise control of the fiber length and dispersion uniformity to ensure the performance of the final product. Next, the fiber slurry is passed through a screen, where under the action of gravity and vacuum, the fibers intertwine to form a moist fiber web. This step is crucial for determining the uniformity and strength of the surface mat. Then, this wet mat is immersed in an adhesive bath for impregnation. The choice of adhesive is vital, as it not only determines the physical properties of the surface mat, such as strength and softness, but also affects its compatibility with subsequent resins. Finally, the adhesive-impregnated wet mat is sent into an oven for high-temperature drying and curing to form the final Fiberglass Tissue Mat product.

Core Functions in Composite Materials

The reason why a Fiberglass Tissue Mat is so widely used is that it provides multiple, key performance enhancements to composite materials. First, it greatly improves the surface quality of the product. When used as the surface layer of a composite material, the uniform fiber distribution effectively covers the surface of the base material, eliminating the "texture" caused by fiber fabrics, and making the product's surface smooth and flat. This is crucial for products that require a high-gloss finish, such as automotive parts and yacht hulls. Secondly, it significantly enhances the product's corrosion resistance and anti-aging capabilities. The Fiberglass Tissue Mat itself has excellent chemical stability and weather resistance, and it can act as an effective protective barrier against chemical media penetration and UV degradation, thereby extending the product's service life. Furthermore, it can improve the interlayer adhesion of composite materials, preventing delamination, and enhancing their mechanical properties. For example, in structures like pipes, storage tanks, and wind turbine blades, using a Fiberglass Tissue Mat can effectively prevent the initiation and propagation of microcracks, thereby increasing the overall strength and toughness of the structure.

How to Choose the Right Surface Mat Based on Specific Needs

Given the wide array of Fiberglass Tissue Mat products on the market, making the right choice is crucial. The selection should be based on a comprehensive consideration of multiple factors. The most basic consideration is weight and thickness, as they directly determine the fiber content and density of the surface mat, which in turn affects its strength and permeability. For example, for surface smoothing, a low-weight, high-permeability product is usually chosen, while a higher weight might be needed for structural reinforcement. Another key factor is the type of adhesive. Different adhesives can be chosen for different application scenarios. For instance, polyester-based resin systems typically use a surface mat with a polyester adhesive, while epoxy resin systems require a specially designed adhesive to ensure good compatibility. Additionally, many Fiberglass Tissue Mat products are endowed with special functionalities. For example, to meet the fire safety requirements of buildings and vehicles, there are special flame-retardant surface mats; for special environments, there are also functional products with conductive, waterproof, and other properties.

Future Development Trends of Fiberglass Tissue Mat

As a foundational material, the future development of Fiberglass Tissue Mat will be closely tied to trends in environmental protection, functionality, and intelligence. In response to the global call for sustainable development, the industry is actively researching and developing eco-friendly surface mats using recyclable or bio-based adhesives to reduce environmental impact. At the same time, to meet more complex and demanding application requirements, the functionalization of Fiberglass Tissue Mat will become a major direction. In addition to existing flame-retardant and conductive functions, future products may integrate more features, such as temperature sensing and self-healing capabilities, to give composite materials "smart" properties. With the rapid development of emerging industries like wind power, new energy vehicles, and lightweight construction, the application fields of Fiberglass Tissue Mat will continue to expand, and its position in modern manufacturing will become even more solidified.

English

English 中文简体

中文简体 русский

русский Español

Español