Professional Application of Carbon Fiber Cloth in Automotive Repair

In the fields of high-end automotive repair and performance modification, the application of carbon fiber cloth has become increasingly common. It is not only used for appearance decoration but more often as a structural reinforcement material. When body panels, bumpers, or internal structural components of a vehicle develop cracks or require local strengthening, carbon fiber cloth provides a lightweight and high-strength solution. The repair process typically involves meticulously sanding and cleaning the damaged area, then applying multiple layers of pre-impregnated carbon fiber cloth. After pressing and curing, the strength of the repaired area can even exceed that of the original material. This technique not only fixes the damage but also enhances the component's performance to some extent, meeting the demands of racing and high-performance modified cars that pursue extreme lightweight and rigidity.

The Key to Successful Bonding: The Collaborative Mystery of Epoxy Resin and Carbon Fiber Cloth

Although carbon fiber cloth itself possesses extremely high strength, it must rely on epoxy resin as a matrix to bond it into a whole and transfer loads, a process known as composite material molding. The choice of epoxy resin is crucial; it needs to have low viscosity, good wettability, and ultimately high strength and toughness. The correct mixing ratio of resin to hardener is a prerequisite for ensuring the complete progression of the curing reaction; any deviation can result in a final product that is sticky, brittle, or lacks strength. The process of applying the resin requires patience and skill. It is essential to ensure that every fiber tow is fully encapsulated in resin while trying to avoid introducing excessive air bubbles, as these bubbles can become stress concentration points, reducing the overall performance of the finished product.

Core Steps of Surface Pretreatment

Any successful bond starts with perfect surface preparation. The surface of the substrate to be repaired or reinforced must be thoroughly cleaned to remove all oil, dust, and moisture. This is followed by roughening, typically done with sandpaper, which not only increases the bonding surface area but also provides mechanical locking points. For some smooth non-metallic or metallic surfaces, specific primers may be needed to enhance the chemical bonding between the epoxy resin and the substrate. Neglecting or improperly executing surface pretreatment will directly lead to debonding of the carbon fiber layer from the substrate, causing the entire reinforcement or repair project to fail.

Best Practices for Mixing and Applying Resin

When mixing epoxy resin and hardener, use clean containers and stirring sticks, and strictly weigh the components according to the ratio specified in the product instructions. Stirring should be slow and thorough, scraping the sides and bottom of the container to ensure even mixing, a process that usually takes two to three minutes. Letting the mixture sit for a moment after stirring helps air bubbles escape. During application, first brush a thin layer of resin onto the prepared substrate as a primer. Then, lay the pre-cut carbon fiber cloth on top. Using a brush or roller dipped in resin, gradually press and brush from the center of the cloth outward, forcing the resin to penetrate the fibers and expel trapped air bubbles. Repeat this process until the desired number of layers is achieved.

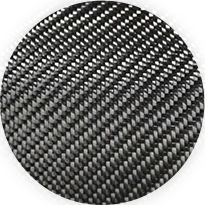

Choosing the Right Material: Interpreting Carbon Fiber Cloth Weight and Thickness Parameters

The specifications of carbon fiber cloth are usually indicated by its weight per unit area (areal weight, e.g., 200g/m², 300g/m²) and weave density. The areal weight directly affects the thickness of the finished product and the amount of material used; a higher areal weight means thicker cloth and greater strength per layer. Selection involves balancing strength requirements, weight limitations, and application convenience. For parts with complex curves or requiring multiple layers, cloth with a lower areal weight is easier to conform and less prone to wrinkling. For flat surfaces or projects prioritizing efficiency, cloth with a higher areal weight can be chosen to reduce the number of layers. Understanding these parameters helps in making the most economical and effective choice based on specific project needs.

Beyond Industry: Exploring the Potential of Carbon Fiber Cloth in DIY Creative Projects

The application of carbon fiber cloth extends far beyond the industrial sector; it has entered the workshops of countless hobbyists and artists. Its unique black woven texture and futuristic technological feel make it an ideal material for creating personalized items. From reinforcing drone frames and making lightweight model parts to creating unique phone cases, laptop shells, and even art sculptures and furniture veneers, carbon fiber cloth provides a solid foundation for realizing creativity. The DIY process allows creators full control over the shape and details of their work, experiencing the complete joy of creation from design to finished product.

Clarifying Concepts: The Essential Difference Between Carbon Fiber Cloth and Carbon Fiber Tow

Although carbon fiber cloth and carbon fiber tow share the same origin, their forms and uses are significantly different. Carbon fiber cloth is a sheet fabric woven from carbon fiber filaments, offering good drapeability that allows it to easily cover molds or workpieces, making it suitable for most scenarios requiring surface reinforcement. Carbon fiber tow, on the other hand, refers to a bundle of unwoven, parallel continuous carbon filaments, usually supplied on spools. Tow is primarily used for filament winding processes, such as manufacturing pipes and gas cylinders, or for pultrusion processes to create profiles. Its fiber direction is highly aligned, providing extremely high strength in a single direction but lacking transverse stability.

English

English 中文简体

中文简体 русский

русский Español

Español