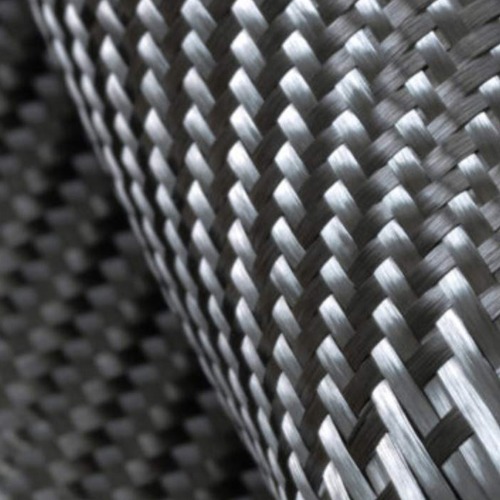

When discussing advanced materials in the modern world, carbon fiber cloth undoubtedly holds a pivotal position. It is not a simple fabric but a precision-woven material composed of countless carbon fiber tows, each with a diameter only one-tenth that of a human hair. Its core allure lies in a seemingly contradictory trait: extremely high strength paired with extremely low weight. This unique performance stems from its microstructure—carbon atoms arranged in a hexagonal grid, forming a graphite-like layered structure bound tightly by covalent bonds. This structure endows it with unparalleled tensile strength and rigidity, while its primary component (carbon) results in a density far lower than traditional metal materials.

Thus, carbon fiber cloth can significantly enhance structural load-bearing capacity and fatigue resistance without notably increasing self-weight. From key aerospace components and F1 racing car bodies to bridge and building reinforcement, carbon fiber cloth is quietly transforming our world with its unique advantages.

One Cloth, One World: How to Choose Different Specifications of Carbon Fiber Cloth

Carbon fiber cloth is not a one-size-fits-all product; its specifications and performance vary greatly, and selecting the right material is the first step toward successful application. When evaluating carbon fiber cloth, focus on these core parameters:

- Gram Weight: Represents weight per unit area, usually measured in grams per square meter (g/㎡). A higher gram weight means more fiber content per unit area, yielding greater strength but also increased thickness, making it harder to conform to curved surfaces.

- Weaving Pattern: Common types include plain weave, twill weave, and unidirectional cloth. Plain and twill weaves offer good isotropy (uniform strength across directions), suitable for scenarios with high aesthetic requirements. Unidirectional cloth, with most fibers aligned in one direction, provides extreme unidirectional tensile strength—ideal for structural reinforcement and load-bearing enhancement.

- Modulus Grade: Classified as high, medium, or standard modulus. Higher modulus means better rigidity but higher cost.

Understanding and balancing these parameters allows you to select the carbon fiber cloth that best delivers value for specific applications, whether for reinforcement, aesthetic modification, or lightweight manufacturing.

The Invisible “Skeleton”: How Carbon Fiber Cloth Reinforces Buildings

In construction engineering, carbon fiber cloth has become an efficient, reliable structural reinforcement material—dubbed the “invisible skeleton.” When concrete structures develop cracks, insufficient load-bearing capacity, or damage from long-term use, design flaws, or earthquakes, traditional reinforcement methods often require large-scale demolition and modification, which are time-consuming and labor-intensive.

Carbon fiber cloth offers a lightweight, efficient solution. Its principle relies on extremely high tensile strength: when bonded to concrete surfaces using specialized epoxy resin adhesives, it acts like a tough “coat” for the component. This constrains concrete to prevent further crack expansion, shares tensile stress, and significantly improves structural seismic resistance, load-bearing capacity, and durability.

The construction process requires no heavy equipment, minimally impacts the original structure, and has a short cycle—greatly reducing reinforcement costs and disruption to normal use. It is particularly suitable for reinforcing bridges, tunnels, columns, and beams.

The Art of Performance: The Golden Partnership Between Carbon Fiber Cloth and Resin

The exceptional performance of carbon fiber cloth is not standalone; it relies on a suitable matrix material—epoxy resin—to unleash its full potential. Epoxy resin plays a critical role in this system:

- It acts as the “glue” bonding carbon fiber cloth to the reinforced component.

- It integrates countless carbon fiber tows into a unified structure, enabling them to work synergistically.

Under load, epoxy resin evenly transfers external forces from concrete to each carbon fiber, avoiding stress concentration and local failure. Additionally, it protects carbon fibers from environmental erosion.

Choosing an epoxy resin system compatible with the carbon fiber cloth is therefore crucial. Different resins vary in viscosity, curing time, strength, and weather resistance. In practice, the right resin must be selected based on construction temperature, humidity, and required final curing strength to ensure bonding reliability and durability.

Beyond Reinforcement: How Carbon Fiber Cloth Drives the Lightweight Revolution

Beyond its outstanding performance in building reinforcement, carbon fiber cloth is spearheading a revolution in lightweight design.

- Automotive Industry: To meet stricter fuel consumption and emission regulations, reducing vehicle weight is key. Body parts made with carbon fiber cloth—such as hoods, doors, and chassis—weigh only one-fourth of traditional steel parts while offering superior strength and safety. This lightweight design directly improves acceleration, handling, fuel efficiency, and reduces carbon emissions.

- Aerospace: Every gram saved translates to significant cost reductions and performance gains. Aircraft wings, fuselages, and tail sections made with carbon fiber composites allow planes to carry more passengers/cargo or achieve longer ranges.

Through carbon fiber cloth’s lightweight technology, industries are moving toward a more efficient, energy-saving, and sustainable future.

English

English 中文简体

中文简体 русский

русский Español

Español