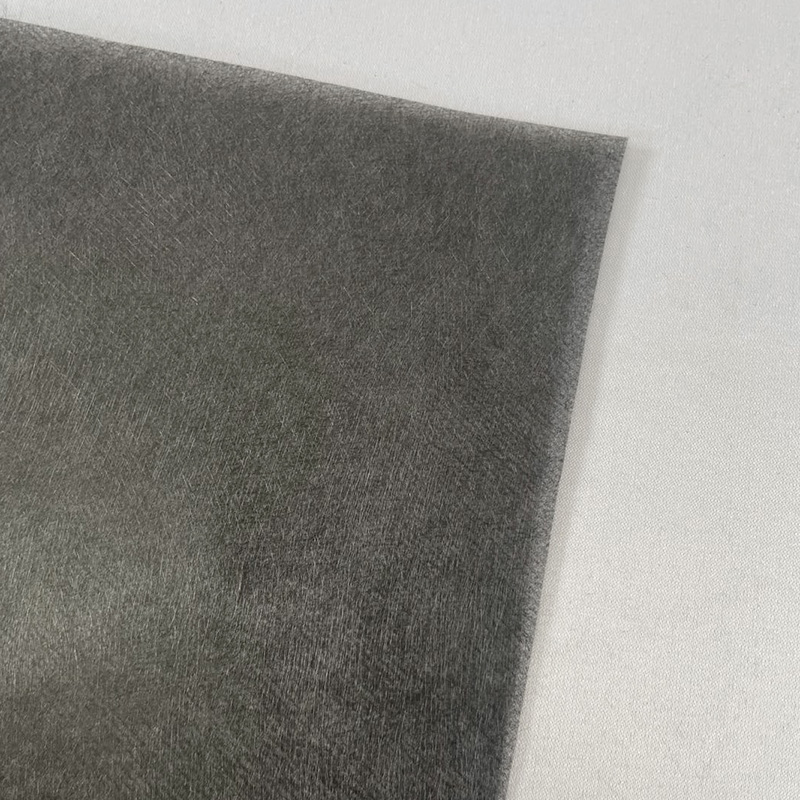

Unique Composition and Lightweight Properties

Grey 20g abrasion-resistant carbon fiber surface felt is engineered with meticulous precision to offer a remarkable balance of lightweight characteristics and high mechanical strength, which is essential for modern industrial applications. The felt consists of ultra-fine carbon fibers, which are interlaced to form a dense yet flexible matrix. This unique composition ensures that the material maintains structural integrity while remaining extremely light, reducing the load on machinery and enhancing operational efficiency. The felt's density and thickness are carefully calibrated to provide cushioning against mechanical stresses, vibration, and thermal expansion, making it highly versatile. In industries where every gram matters, such as aerospace, automotive, and robotics, using lightweight materials like this felt can significantly improve energy efficiency, speed, and overall performance.

Exceptional Durability and Abrasion Resistance

The Grey 20g carbon fiber surface felt exhibits exceptional durability that allows it to withstand harsh industrial environments, including high friction, repeated impact, and exposure to abrasive particles. Its abrasion resistance is derived from the inherent properties of carbon fibers, which have an extremely high tensile strength and low wear coefficient. Unlike traditional fabrics or metallic sheets that degrade under constant friction, this felt maintains its surface integrity over prolonged use, reducing downtime for repairs or replacements. Furthermore, its chemical stability enables it to resist corrosion, oils, and mild acids, which is critical in chemical plants, machining operations, and other demanding settings. As a result, industries can benefit from significantly extended service life, predictable performance, and lower long-term maintenance costs.

Versatile Applications Across Industries

The applications of Grey 20g abrasion-resistant carbon fiber felt are vast and varied, spanning multiple industrial sectors. In automotive manufacturing, it is utilized as a lightweight insulating layer to reduce noise and vibration while simultaneously protecting metal panels from wear. In aerospace, its combination of low weight and high strength contributes to fuel efficiency and structural reinforcement of aircraft interiors and equipment housings. In electronics and high-tech manufacturing, the felt provides anti-static and thermal insulation properties while protecting sensitive components during production. Additionally, it is often used as a protective layer in heavy machinery to shield moving parts from abrasion, extend service intervals, and improve operational reliability. Its adaptability allows engineers to tailor the felt to specific thicknesses, densities, and surface finishes according to application requirements, making it a highly flexible material solution.

Easy Handling and Integration into Existing Systems

Despite its high-performance characteristics, Grey 20g carbon fiber surface felt is remarkably easy to handle and implement in existing industrial systems. The felt can be cut, molded, or layered without specialized machinery, facilitating rapid integration into production lines or retrofitting older equipment. Its flexible structure enables it to conform to complex geometries and uneven surfaces, providing continuous coverage without compromising performance. Additionally, its lightweight nature simplifies transportation, storage, and installation, reducing labor costs and minimizing safety risks associated with heavier materials. For industries seeking to upgrade protective layers or enhance component longevity, the simplicity of handling this felt ensures minimal disruption to operational workflows.

Cost-Effectiveness Compared to Alternative Materials

Grey 20g abrasion-resistant carbon fiber felt represents a cost-effective alternative to heavier, more rigid materials such as metals or multilayer composites. Its low maintenance requirements, long service life, and ease of installation reduce both direct and indirect costs. Over time, the felt can significantly lower expenditures related to equipment replacement, energy consumption, and labor-intensive maintenance. Compared to traditional protective layers, which may require frequent inspection and replacement due to wear, this felt maintains consistent performance under challenging conditions. Furthermore, industries can benefit from a reduction in overall material consumption, as the felt’s high strength-to-weight ratio allows for thinner, lighter applications without sacrificing protection. This balance of economic efficiency and high performance positions the material as a strategic choice for industries aiming to optimize both operational costs and product longevity.

English

English 中文简体

中文简体 русский

русский Español

Español