Understanding Pultruded Carbon Fiber Composite Felt

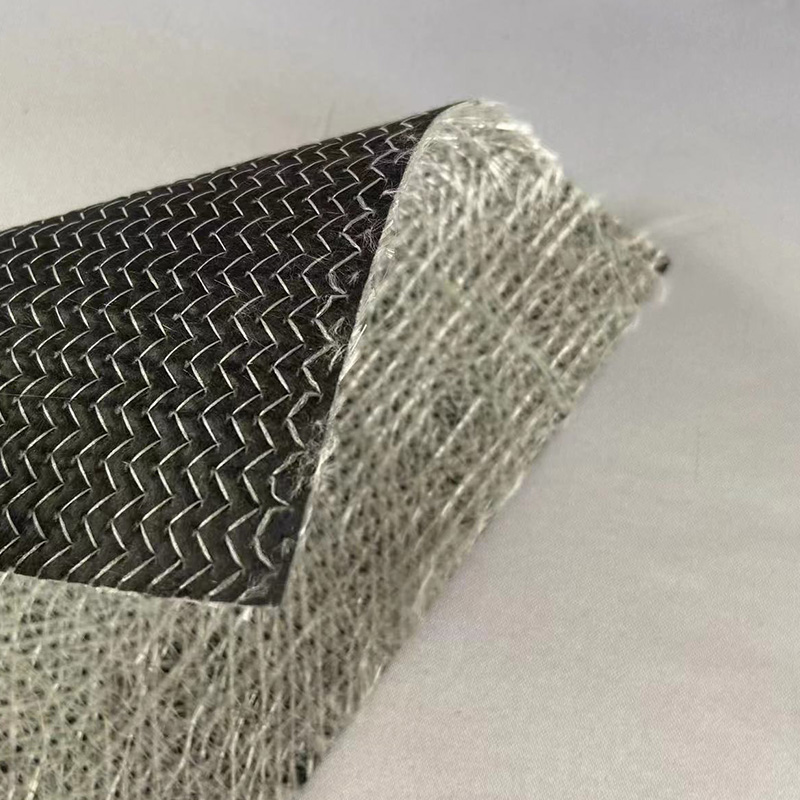

Pultruded carbon fiber composite felt represents a significant advancement in specialized material science, combining the traditional benefits of carbon fiber with a unique manufacturing process. The pultrusion technique involves pulling continuous strands of carbon fiber through a resin impregnation bath and then through a heated die to cure the composite into a specific, consistent profile. This method results in a material with exceptionally high unidirectional strength-to-weight ratio and superior dimensional stability compared to non-woven or randomly oriented felts. The specific weight of 300 grams per square meter indicates a material that is substantial enough for robust structural applications while remaining remarkably lightweight. The integration of conductive properties directly into the composite matrix during manufacturing ensures that the electrical and thermal conductivity are intrinsic characteristics, not just surface-level treatments, making it a fundamentally functional material for demanding engineering environments.

Exceptional Performance as an EMI Shielding Solution

The proliferation of electronic devices across all industries has made electromagnetic interference (EMI) shielding a critical design consideration, and pultruded carbon fiber felt is an increasingly preferred material to address this challenge. Its continuous carbon fiber network creates a highly effective conductive path that reflects and absorbs electromagnetic waves, preventing them from interfering with sensitive electronic components. Unlike metallic shields, which can be heavy and prone to corrosion, this composite felt offers a lightweight and chemically inert alternative. The pultrusion process allows for the creation of complex, thin-profile shields that can be integrated directly into device housings or structural panels, saving space and weight. This makes it an ideal solution for applications in telecommunications infrastructure, medical imaging equipment, and military electronics, where signal integrity is paramount and weight savings are a crucial advantage.

Lightweight Conductivity for Demanding Aerospace Components

In the aerospace sector, every gram saved translates directly into improved fuel efficiency, increased payload capacity, and enhanced performance. The combination of low density and high electrical conductivity makes 300g pultruded carbon fiber felt an invaluable material for a multitude of aerospace applications. It is particularly suited for components that require both structural integrity and specific functional properties, such as lightning strike protection systems integrated into aircraft skins. The material's ability to safely dissipate the immense electrical energy from a lightning strike without compromising the airframe's structural integrity is a key benefit. Furthermore, its conductive nature allows it to be used for grounding applications and as a lightweight replacement for metal brackets and frames in areas where static dissipation or EMI shielding is required, contributing to the overall safety and reliability of the aircraft.

A Crucial Role in Advanced Thermal Management Systems

Effective thermal management is a cornerstone of modern technology, from high-performance computing to power electronics, and pultruded carbon fiber composite felt excels in this domain. The material's high thermal conductivity allows it to rapidly draw heat away from sensitive components, acting as a heat spreader that prevents the formation of damaging hot spots. Its felted, porous structure can also be engineered to facilitate even heat distribution across a larger surface area, improving the efficiency of attached heat sinks or cooling fins. In systems like fuel cells, this material is investigated for use as bipolar plates, where it must conduct electrical current between cells while also managing the heat generated by the electrochemical reactions. Its stability at elevated temperatures ensures consistent performance, making it a reliable solution for managing thermal loads in compact, high-power-density systems.

Durability and Reliability in Harsh Industrial Environments

Beyond the clean rooms and controlled environments of electronics and aerospace, pultruded carbon fiber felt proves its mettle in rugged industrial settings. Its inherent corrosion resistance is a major advantage over metals, as it does not rust or degrade when exposed to moisture, chemicals, or saline atmospheres. This property is essential for applications such as industrial heating elements, where the material can serve as a durable, conductive heater blanket for process heating, de-icing, or composite curing. The composite's resistance to chemical attack also makes it suitable for use in chemical processing equipment as a conductive lining or as part of filtration systems that require electrostatic charge. The robust nature of the pultruded profile ensures it maintains its shape and mechanical properties under continuous mechanical stress and thermal cycling, providing long-term operational reliability.

Key Considerations for Material Selection and Customization

Selecting the right specialized composite requires a deep understanding of the application's specific requirements. While the 300g weight provides a good balance of properties, the pultrusion process is highly adaptable, allowing for customization of the resin system, fiber type, and profile geometry to meet precise needs. Engineers must consider factors such as the required level of electrical conductivity or EMI shielding effectiveness, the operational temperature range, the mechanical load bearing capacity, and the environmental exposure conditions. Collaborating with material scientists and manufacturers early in the design phase is crucial to tailor the composite's characteristics, whether it involves optimizing the fiber-to-resin ratio for enhanced conductivity or selecting a high-temperature resin for thermal stability. This collaborative and customized approach ensures that the final pultruded carbon fiber felt component delivers optimal performance and integration within the broader system.

English

English 中文简体

中文简体 русский

русский Español

Español