Carbon Fiber Yarn Suppliers

It is a kind of yarn spun from short carbon fibers, mainly used insulation materials, anti-friction materials, composite parts, etc.

-

How Does Roofing Tissue Improve the Durability of Roofing Systems?

Roofing systems are essential in providing protection to buildings from harsh weather conditions, ensuring safety and energy efficiency. The...

READ MORE -

How Durable Is Carbon Fiber Cloth in Extreme Conditions?

Introduction Carbon fiber cloth is quickly becoming one of the sought-after materials across various industries due to its unique properties...

READ MORE -

How to Choose the Right Glass Fiber Mat for Your Project?

When working on a project that requires strong, durable, and heat-resistant materials, selecting the right glass fiber mat is crucial. Glass...

READ MORE -

Key Functions of Fiberglass Surfacing Veil in Composite Materials

In recent years, composite materials have gained significant traction across a wide range of industries due to their impressive strength-to-...

READ MORE -

Chopped Strand vs. Continuous Filament: Types of Glass Fiber Mats Explained

Glass fiber mats are a staple in various industries, serving as critical components in applications ranging from construction to automotive ...

READ MORE

What are the advantages of Carbon Fiber Yarn compared to standard fiber substances (which include cotton, polyester, etc.)?

Compared with conventional fiber materials, Carbon Fiber Yarn has the subsequent blessings:

1. **High Strength and Lightweight**: The strength of Carbon Fiber Yarn is higher than steel, and its unique gravity is much lighter, which permits it to offer higher power and stiffness at the identical weight.

2. **Excellent corrosion resistance**: Carbon Fiber Yarn may be used for a long time without being subject to chemical corrosion, which makes its utility in harsh environments extra dependable.

3. **Excellent excessive temperature resistance**: Carbon Fiber Yarn can maintain balance in high temperature environments and isn't smooth to soften or deform, which makes it superb in high temperature packages.

4. **Good fatigue performance**: Carbon Fiber Yarn has notable fatigue strength and may maintain strong performance below long-time period repeated loading.

5. **High diploma of design freedom**: Carbon Fiber Yarn can be made into diverse shapes and systems through distinctive weaving strategies and approaches, giving it greater flexibility and freedom in design.

6. **Electrical and thermal conductivity**: Carbon Fiber Yarn has awesome electric and thermal conductivity and is suitable for packages requiring those properties.

7. **Excellent tensile properties**: Carbon Fiber Yarn has exquisite tensile homes, giving it an advantage in packages that need to face up to high tensile or extrusion forces.

8. **Strong fatigue resistance**: Carbon Fiber Yarn isn't at risk of fatigue fracture all through long-time period use, and can maintain stable performance and make bigger product existence.

How to ensure best manipulate of Carbon Fiber Yarn?

Ensuring pleasant control of Carbon Fiber Yarn is important to ensure the very last product meets patron needs and standards. Here are a few approaches to make sure pleasant control of Carbon Fiber Yarn:

1. **Raw material fine control**: Ensure that awesome carbon fiber is used as uncooked fabric and strictly control its first-rate, together with fiber diameter, fiber period, purity and other parameters.

2. **Manufacturing Process Monitoring**: Implement strict manufacturing manner manipulate, monitor parameters and signs at each manufacturing level, and ensure that merchandise meet the desired technique requirements.

3. **Equipment and Process Control**: Ensure the stability and reliability of production system and method glide, and often check out and preserve equipment to make certain its regular operation.

4. **Quality Inspection and Testing**: Implement comprehensive pleasant inspection and checking out approaches, which include uncooked cloth trying out, intermediate product testing and very last product checking out, to ensure that products meet great standards and purchaser requirements.

5. **Continuous Improvement and Feedback Mechanism**: Continuously enhance the first-class management device and introduce superior technologies and strategies to improve product nice and production performance. At the same time, an effective consumer comments mechanism is established to handle patron lawsuits and tips in a well timed manner.

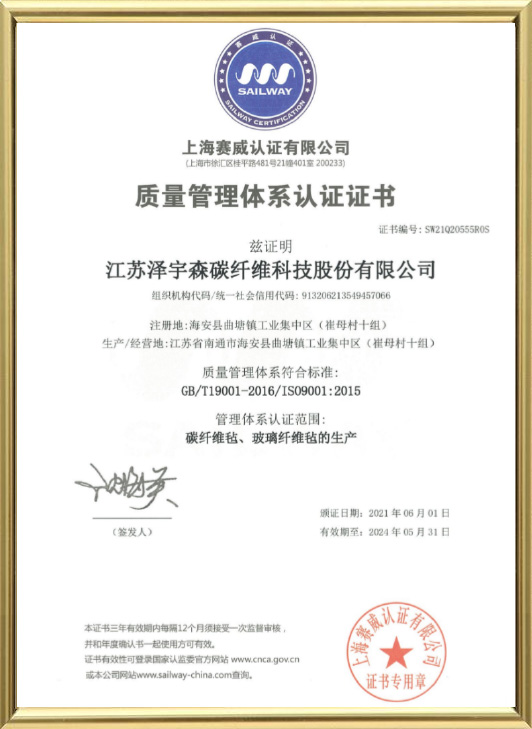

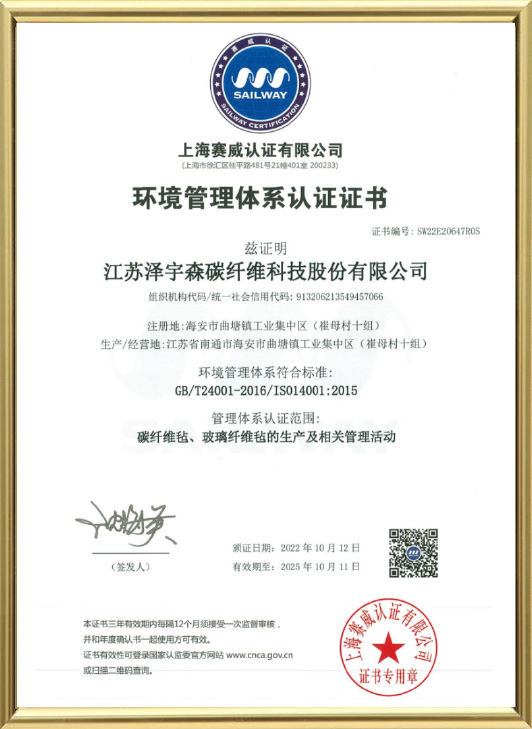

6. **Quality Certification System**: Obtain relevant best certifications, consisting of ISO 9001 excellent control system certification, to show that products meet worldwide satisfactory requirements and beautify product competitiveness.

7. **Employee schooling and best improvement**: Provide everyday training to employees to improve their satisfactory attention and technical degree, ensuring that they are able to correctly perform system, perform techniques and behavior high-quality inspections.

8. **Supply Chain Management**: Manage the upstream and downstream partners of the deliver chain to make certain the best of raw substances and key additives is controllable and keep away from the impact of first-rate issues on the final product.

English

English 中文简体

中文简体 русский

русский Español

Español