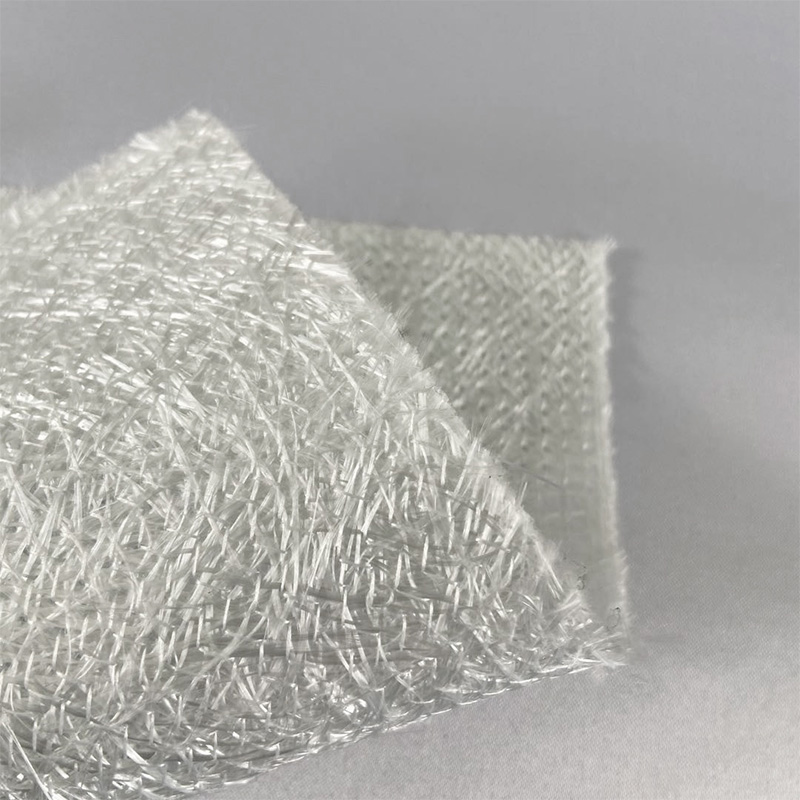

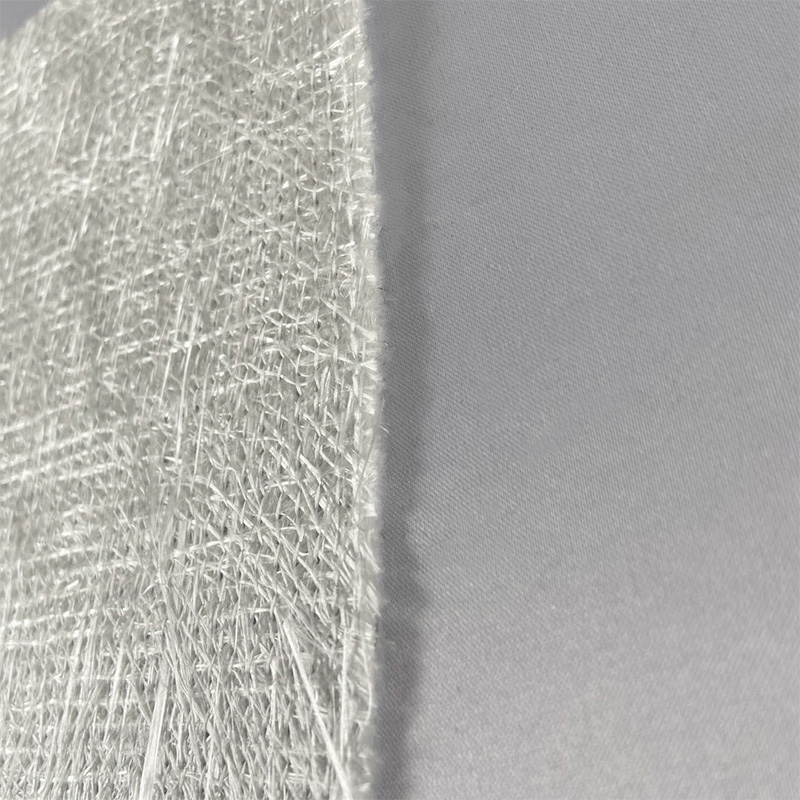

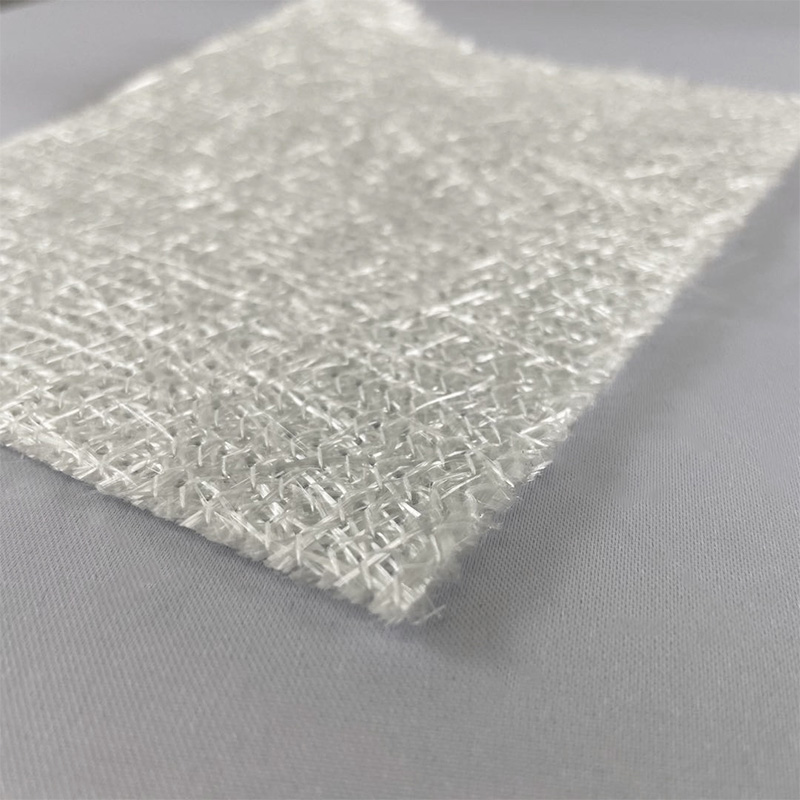

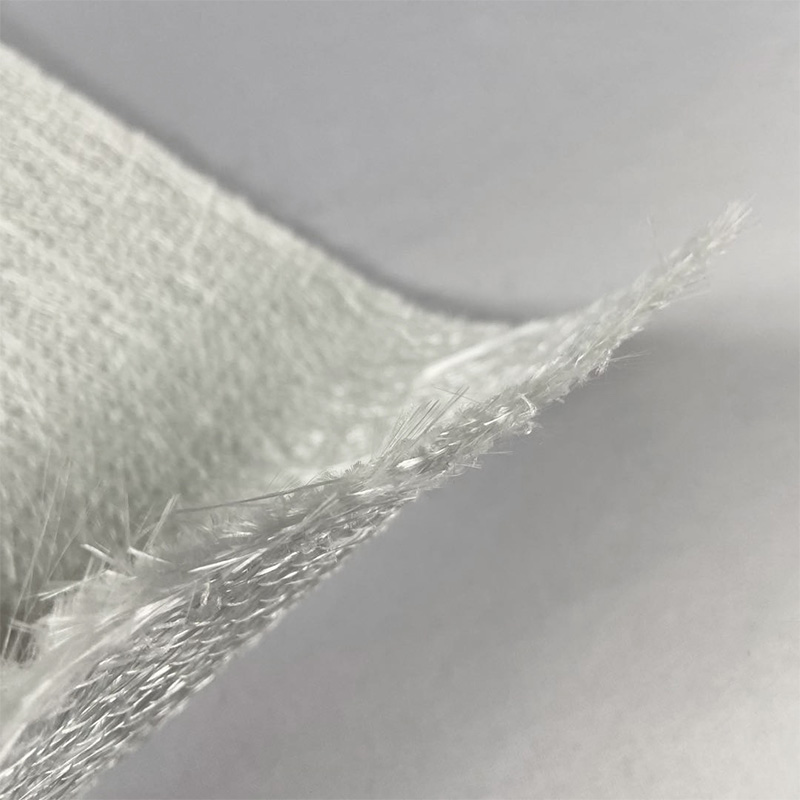

300g Glass Fiber Stitching Felt Knitted Felt

-

How Does Roofing Tissue Improve the Durability of Roofing Systems?

Roofing systems are essential in providing protection to buildings from harsh weather conditions, en...

READ MORE -

How Durable Is Carbon Fiber Cloth in Extreme Conditions?

Introduction Carbon fiber cloth is quickly becoming one of the sought-after materials across various...

READ MORE -

How to Choose the Right Glass Fiber Mat for Your Project?

When working on a project that requires strong, durable, and heat-resistant materials, selecting the...

READ MORE -

Key Functions of Fiberglass Surfacing Veil in Composite Materials

In recent years, composite materials have gained significant traction across a wide range of industr...

READ MORE -

Chopped Strand vs. Continuous Filament: Types of Glass Fiber Mats Explained

Glass fiber mats are a staple in various industries, serving as critical components in applications ...

READ MORE -

Fiberglass Surfacing Veil vs. Fiberglass Mat: What’s the Difference?

In composite manufacturing, construction materials, and industrial insulation systems, fiberglass-ba...

READ MORE

Industry knowledge

Jiangsu Zeyusen Carbon Fiber Technology Co., Ltd. has extensive experience in the field of high-performance carbon fiber and glass fiber materials. How is this experience and technical strength reflected in the quality and performance of the 300g Glass Fiber Stitching Felt Knitted Felt it produces?

1. Rich industry experience

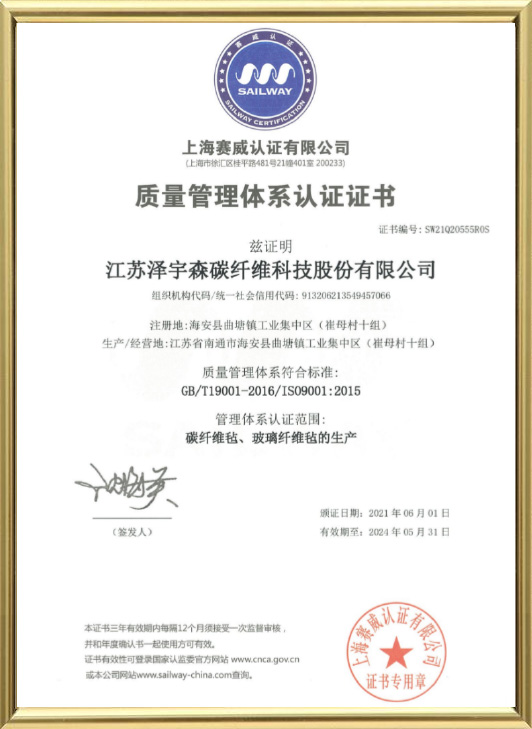

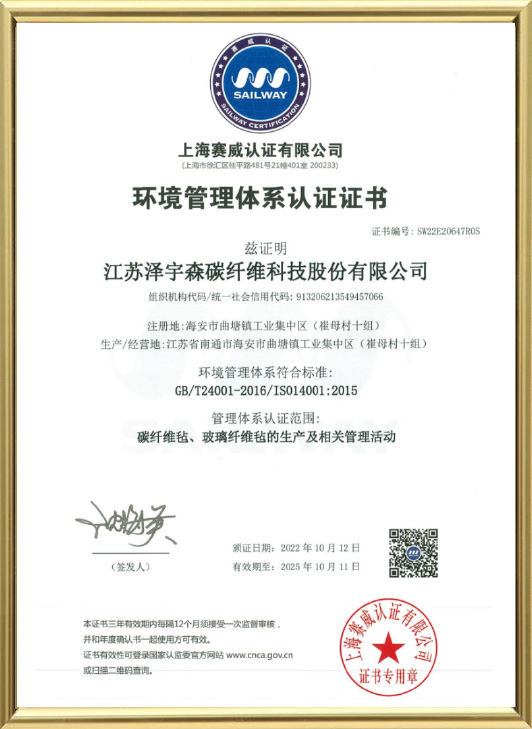

Jiangsu Zeyusen Carbon Fiber Technology Co., Ltd. is located in Nantong City, Jiangsu Province, with production bases in Nantong and Taizhou, Jiangsu. It is a high-tech composite material enterprise integrating scientific research, development and production. Since its establishment, the company has focused on the research and development and production of high-performance carbon fiber and glass fiber materials. With its keen insight into the market and continuous pursuit of technology, it has gradually established a good reputation in the industry. The company not only has a professional team of technical talents, but also relies on the technical support of the Chinese Academy of Sciences, CSG Institute and major universities to form a strong technical research and development backing. The accumulation of this industry experience has given the company significant advantages in material selection, process optimization, quality control, etc.

2. Advanced technical strength

The company has always maintained a persistent pursuit of technological innovation in the research and development of high-performance carbon fiber and glass fiber materials. The company has invested a lot of resources to build advanced laboratories and R&D centers, equipped with high-precision production equipment and testing equipment, providing a solid hardware foundation for product research and development and production. The company also actively introduces advanced technical concepts and production processes from home and abroad to continuously optimize product performance and improve production efficiency.

In the production process of 300g Glass Fiber Stitching Felt Knitted Felt, the company made full use of its advanced technical strength and carried out strict control and optimization from raw material selection to production process. The company selects high-quality glass fiber raw materials and uses a precise knitting process to weave the fibers tightly together to form a 300g glass fiber knitted felt with high strength, high stiffness, high wear resistance and high corrosion resistance. The company also uses advanced heat treatment technology to perform high-temperature treatment on the felt body, further improving the stability and durability of the product.

3. Excellent product quality and performance

Relying on its rich industry experience and advanced technical strength, the company produces 300g glass fiber knitted felt that has reached the industry-leading level in quality and performance. It is specifically manifested in the following aspects:

High strength and high rigidity: 300g glass fiber knitted felt has high strength and rigidity due to the use of high-quality glass fiber raw materials and precise knitting technology. This excellent mechanical property enables the product to maintain stable performance in various complex environments, meeting customers' needs for high-strength and high-rigidity materials.

High wear resistance: In the production process of 300g glass fiber knitted felt, the company adopts special wear-resistant treatment technology, which makes the product have extremely high wear resistance. This wear resistance not only extends the service life of the product, but also reduces maintenance costs for customers.

High corrosion resistance: The glass fiber material itself has good corrosion resistance, and the company has further improved the corrosion resistance of 300g glass fiber knitted felt by optimizing the production process and raw material ratio. This enables the product to maintain stable performance in various harsh corrosive environments, meeting customers' needs for corrosion-resistant materials.

Good stability: The company uses advanced heat treatment technology to treat 300g glass fiber knitted felt at high temperature, making the product have better stability. This stability is not only reflected in the stability of product performance, but also in the stability of product size, making the product less likely to deform or damage during use.

Wide range of application fields: Due to the excellent properties of 300g glass fiber knitted felt, it is widely used in construction, transportation, aerospace, new energy and other fields. The company's products not only enjoy a high reputation in the domestic market, but are also exported to many countries and regions overseas, winning wide acclaim from domestic and foreign customers.

English

English 中文简体

中文简体 русский

русский Español

Español