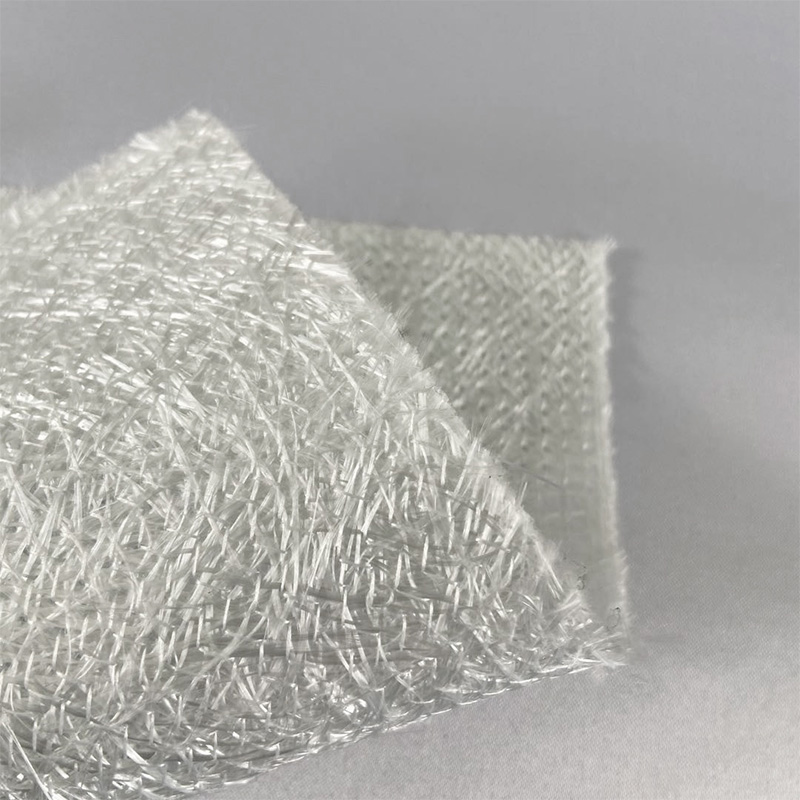

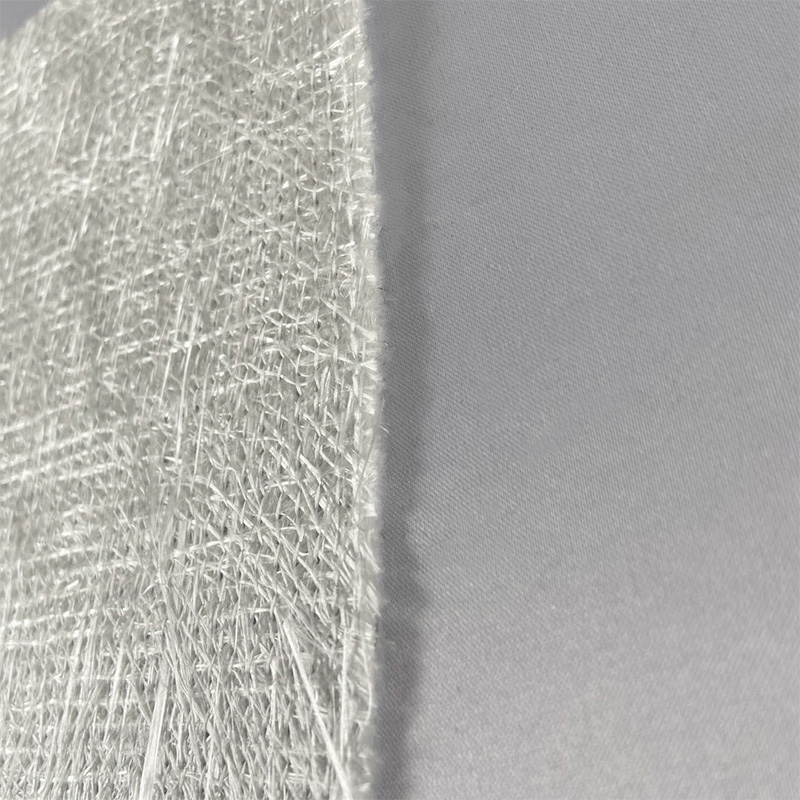

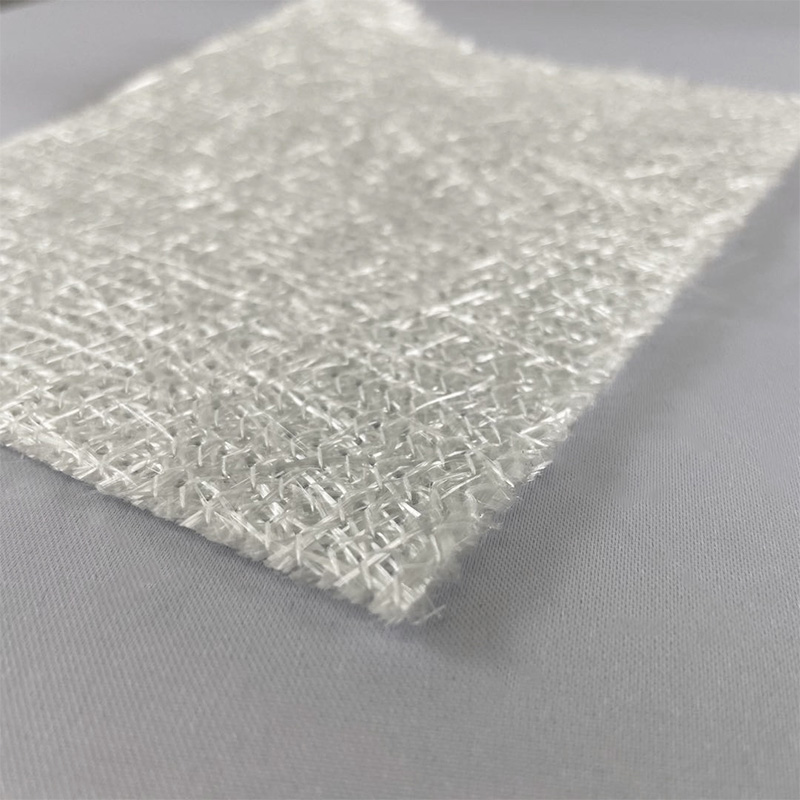

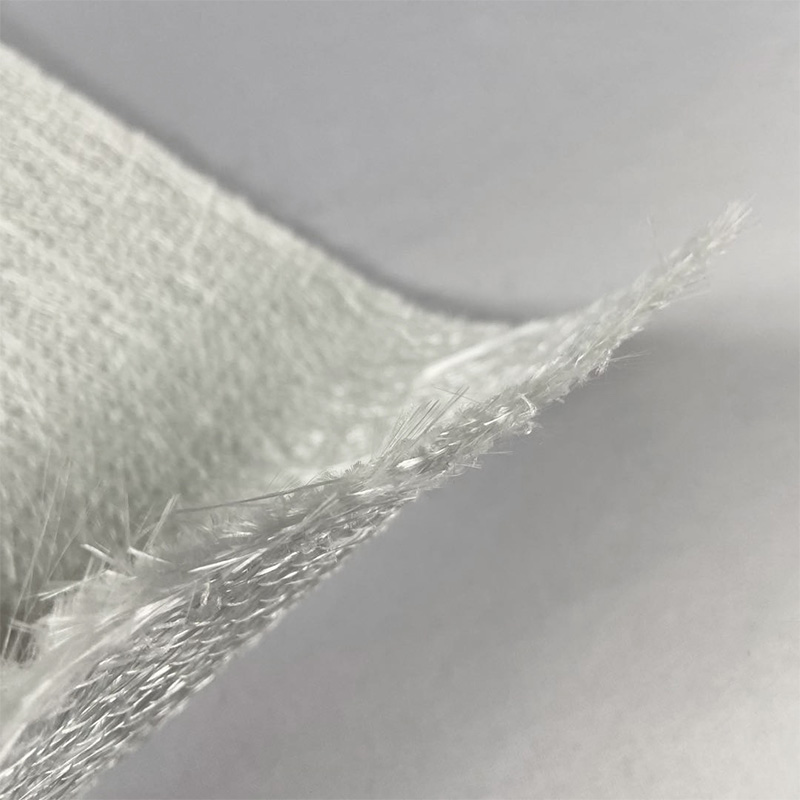

450g Glass Fiber Stitching Edge Felt Knitted Felt

-

How Does Roofing Tissue Improve the Durability of Roofing Systems?

Roofing systems are essential in providing protection to buildings from harsh weather conditions, en...

READ MORE -

How Durable Is Carbon Fiber Cloth in Extreme Conditions?

Introduction Carbon fiber cloth is quickly becoming one of the sought-after materials across various...

READ MORE -

How to Choose the Right Glass Fiber Mat for Your Project?

When working on a project that requires strong, durable, and heat-resistant materials, selecting the...

READ MORE -

Key Functions of Fiberglass Surfacing Veil in Composite Materials

In recent years, composite materials have gained significant traction across a wide range of industr...

READ MORE -

Chopped Strand vs. Continuous Filament: Types of Glass Fiber Mats Explained

Glass fiber mats are a staple in various industries, serving as critical components in applications ...

READ MORE -

Fiberglass Surfacing Veil vs. Fiberglass Mat: What’s the Difference?

In composite manufacturing, construction materials, and industrial insulation systems, fiberglass-ba...

READ MORE

Industry knowledge

When producing 450g Glass Fiber Stitching Edge Felt Knitted Felt, how does the company use its advanced laboratories and R&D centers to meet the needs of domestic and foreign customers for special specifications?

1. Advanced laboratories: the cornerstone of quality and innovation

The company's laboratories are equipped with internationally advanced testing and analysis equipment, including but not limited to high-precision electron microscopes, material mechanical properties testers, thermal analyzers, etc. These equipment provide solid hardware support for the development and production of 450g Glass Fiber Stitching Edge Felt Knitted Felt. The laboratory team is composed of experienced material scientists and engineers who use these advanced equipment to strictly screen and test raw materials to ensure that each batch of glass fiber yarns meets specific strength, heat resistance and chemical stability requirements.

During the product development stage, the laboratory team will conduct a large number of material ratio tests to optimize the physical properties and appearance characteristics of the product by adjusting the diameter of the glass fiber, the weaving method and the processing technology of the stitching edge. In particular, for the weight requirement of 450g, the team will accurately control the density and distribution of the fiber to achieve the best weight-to-strength ratio. In addition, the laboratory will also conduct simulated environmental tests, such as performance tests under conditions of high temperature, low temperature, and humidity changes, to ensure the stability and reliability of the product in different application environments.

2. R&D Center: The Engine of Innovation-Driven Development

The company's R&D center is a bridge between the laboratory and the market. It is responsible for converting the laboratory's research results into practical products and continuously optimizing product design and production processes. In response to the special specification requirements of 450g Glass Fiber Stitching Edge Felt Knitted Felt, the R&D center will communicate in depth with customers to understand their specific application scenarios, performance requirements, and cost budgets, so as to customize and develop products that meet customer expectations.

In the product design stage, the R&D center will use computer-aided design (CAD) and computer-aided engineering (CAE) technology to accurately simulate and predict the structure, size, and performance of the product to reduce trial and error costs and improve product development efficiency. At the same time, the team will also explore new weaving technologies and stitching processes to improve the durability and aesthetics of the product. For example, by optimizing the design of the stitching edge, the wear of the product during use can be reduced and the service life can be extended.

3. Technical cooperation: a window to broaden the horizon of innovation

The company is well aware that technological innovation is the key to promoting the sustainable development of the enterprise. Therefore, the company has established long-term and stable cooperative relations with the Chinese Academy of Sciences, CSG Research Institute and major universities to jointly carry out research and application development of cutting-edge materials science. These collaborations not only provide the company with strong technical support and talent reserves, but also broaden its technical vision and innovative ideas.

In the research and development of 450g Glass Fiber Stitching Edge Felt Knitted Felt, the company made full use of these cooperative resources. For example, through cooperation with the Chinese Academy of Sciences, the company introduced advanced nanotechnology to modify the surface of glass fiber, improving its compatibility and bonding strength with other materials; cooperation with CSG Research Institute helped the company achieve breakthroughs in the melt spinning and heat treatment process of glass fiber, further improving the performance and stability of the product. At the same time, cooperation with universities has cultivated a group of young and promising scientific research talents for the company, injecting new vitality into the company's future development.

IV. Meeting special specifications: a model of customized services

It is based on advanced laboratories, efficient R&D centers and a wide range of technical cooperation networks that the company can flexibly respond to the special specifications of 450g Glass Fiber Stitching Edge Felt Knitted Felt from domestic and foreign customers. Whether it is the product's size, weight, strength or appearance requirements, the company can provide customized solutions to ensure that each batch of products can accurately meet customer expectations.

English

English 中文简体

中文简体 русский

русский Español

Español